The Institute of Mineral Processing Machines (IAM) focuses on the research and teaching of the development of energy- and resource-efficient machines for the economic and sustainable processing of primary and secondary raw materials.

Our research fields include:

How can crushers be used to energy-efficiently process gigantic stone boulders into precisely dimensioned grit for house construction?

How can super-solid quartz boulders be ground into finest powder without losing a grain of gold?

Whether it’s in the raw materials, agricultural, chemistry, or pharmacy sector – sieving is imperative! That’s why we do research into new screening methods or airflow classification.

Wet agglomeration – an interesting technology for many industrial sectors with various unexplored technological possibilities! The principle is very similar to the rolling of balls for a snowman – albeit strictly scientific, of course 😉

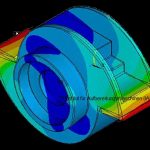

Although there are many experimental opportunities, computer models are sometimes a more suitable solution or just a supplement to better understand certain processes. We model crushing processes by means of the Discrete Element Method (DEM), flows using Computational Fluid Dynamics (CFD), or vibrations via Multi-Body Simulations (MBS).

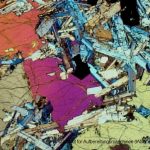

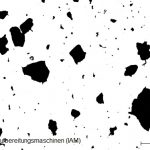

In order to obtain advanced insights into the rock crushing processes, we go into great detail: Through Quantitative Microstructure Analysis (QMA) under the microscope, we are able to make predictions about tool wear and energy requirements for comminution.

Wear is (almost) unavoidable. However, the analysis of the tribological systems enables us to better understand and control the reasons for it.

Fascinating high-speed camera recordings e.g. can track the bursting of a soap bubble very closely. Laser diffraction makes the measurement of even the smallest particles possible. For the slightly larger ones, the Computerized Particle Analyzer (CPA), which measures particles exactly when they fall down, can help us along.