On 06 June 2019, the special colloquium of the IAM on the topic of “Selective Comminution – Improving Recovery and Concentrate Quality” will take place at the TU Bergakademie Freiberg as part of the 70th BHT – Freiberg University Forum.

On 06 June 2019, the special colloquium of the IAM on the topic of “Selective Comminution – Improving Recovery and Concentrate Quality” will take place at the TU Bergakademie Freiberg as part of the 70th BHT – Freiberg University Forum.

Members of the Global Comminution Collaborative (GCC) such as Arno Kwade, Aubrey Mainza, Hakan Benzer, Indresan Govender, Malcolm Powell, Marcello Tavares, Paul Cleary, and other scientists from Bulgaria, Russia, and Germany will contribute to the high-profile program with insightful reports on their latest findings in this field of research.

The colloquium is also part of the 50th anniversary celebrations of the institute.

The earlier special colloquium of the Freiberg Resource Technologies (FRT) group on the latest trends in the beneficiation of tin and tungsten ores on 05 June under the leadership of Dr.-Ing. Max Hesse offers visitors a thematically corresponding additional event.

Selective comminution as an important link in the process chain for the sustainable and efficient mining and preparation of primary raw materials

Within the framework of the 3rd subproject of the “InnoCrush” project of the TU Bergakademie Freiberg, the Institute for Mineral Processing Machines is engaged in the selective comminution of ores and industrial minerals. These raw materials of strategic economic importance particularly occur in the numerous smaller deposits in Saxony or the Saxon Ore Mountains (including tungsten, graphite, and fluorite); however, their potential has hitherto been insufficiently exploited.

Support of Saxony as economic and technology location through the exploitation of its regional deposits

Therefore, the aim of the research project is to strengthen Saxony as industry and innovation location as a result of mining these local deposits sustainably as well as energy-, material-, and cost-efficiently. A further object is the optimization of the entire production chain, comprising the extraction and beneficiation of mineral raw materials.

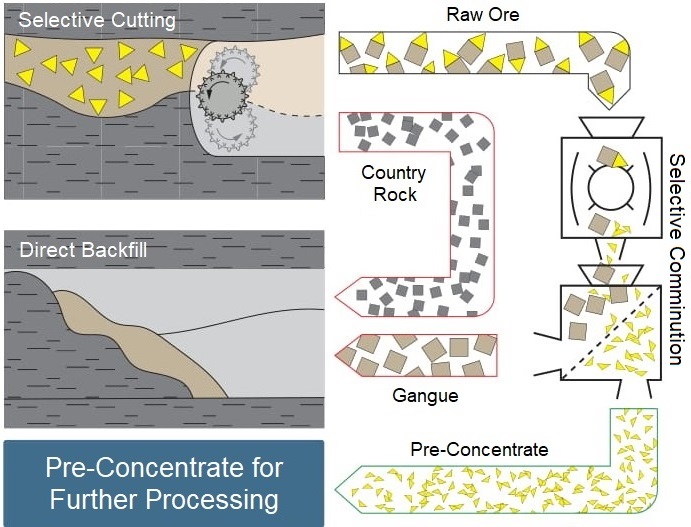

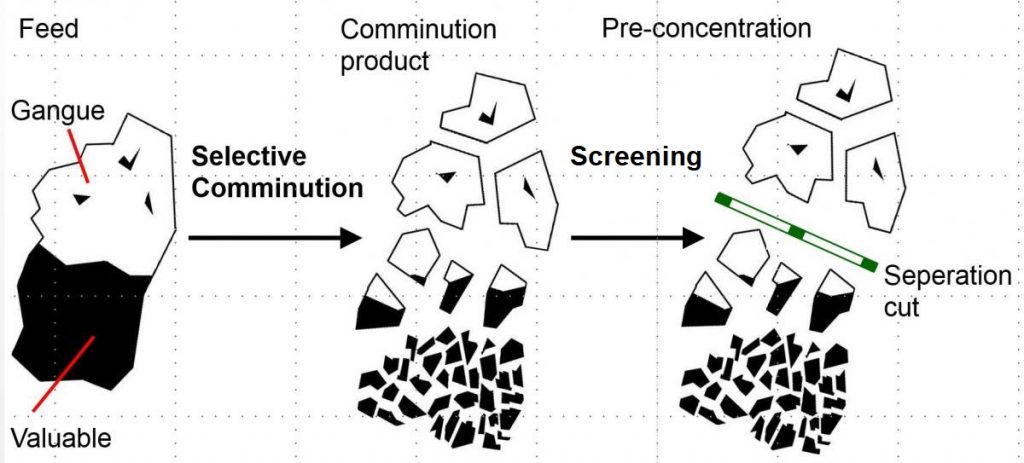

The principle of selective comminution is based on the varying comminution behaviors of valuable and waste components, meaning that materials can be separated primarily due to their differing reactions to mechanical stress. A subsequent screening procedure then divides the comminution product into two fractions via a separation cut: The residual material can be left on site at the mine as backfill, whereas the ore-concentrate will be processed further.

By means of such a pre-classification, the final preparation of the extracted ore-concentrate can be significantly facilitated and accomplished with reduced energy and investment needs.

Pioneering preliminary investigations on selective comminution at the IAM

In order to refine the method of selective comminution as a reliable component in the processing of primary raw materials, further research in the fields of both the fracture processes of mineral rock as well as the development of suitable machinery for targeted particle strain is essential.

Preliminary studies have already been carried out at the Institute for Mineral Processing Machines employing the Quantitative Microstructure Analysis (QMA); in addition, tests on the selective comminution of, inter alia, lead, zinc, and copper ores as well as fluorites and barytes using impact, pressure, shock, and shear stresses have been completed.